Comprehending the Relevance of Professional Stretch Wrap Machine Repair Service for Ideal Efficiency

Stretch Wrap machines play a vital role in the effectiveness of production and logistics procedures. However, they can experience breakdowns that interfere with workflows. Recognizing these issues early is vital for decreasing downtime. Professional repair services supply a remedy, yet several firms neglect their importance. Understanding the benefits of timely repair work can significantly affect operational efficiency and price administration. What aspects should services consider when looking for professional repair work solutions for their stretch Wrap machines?

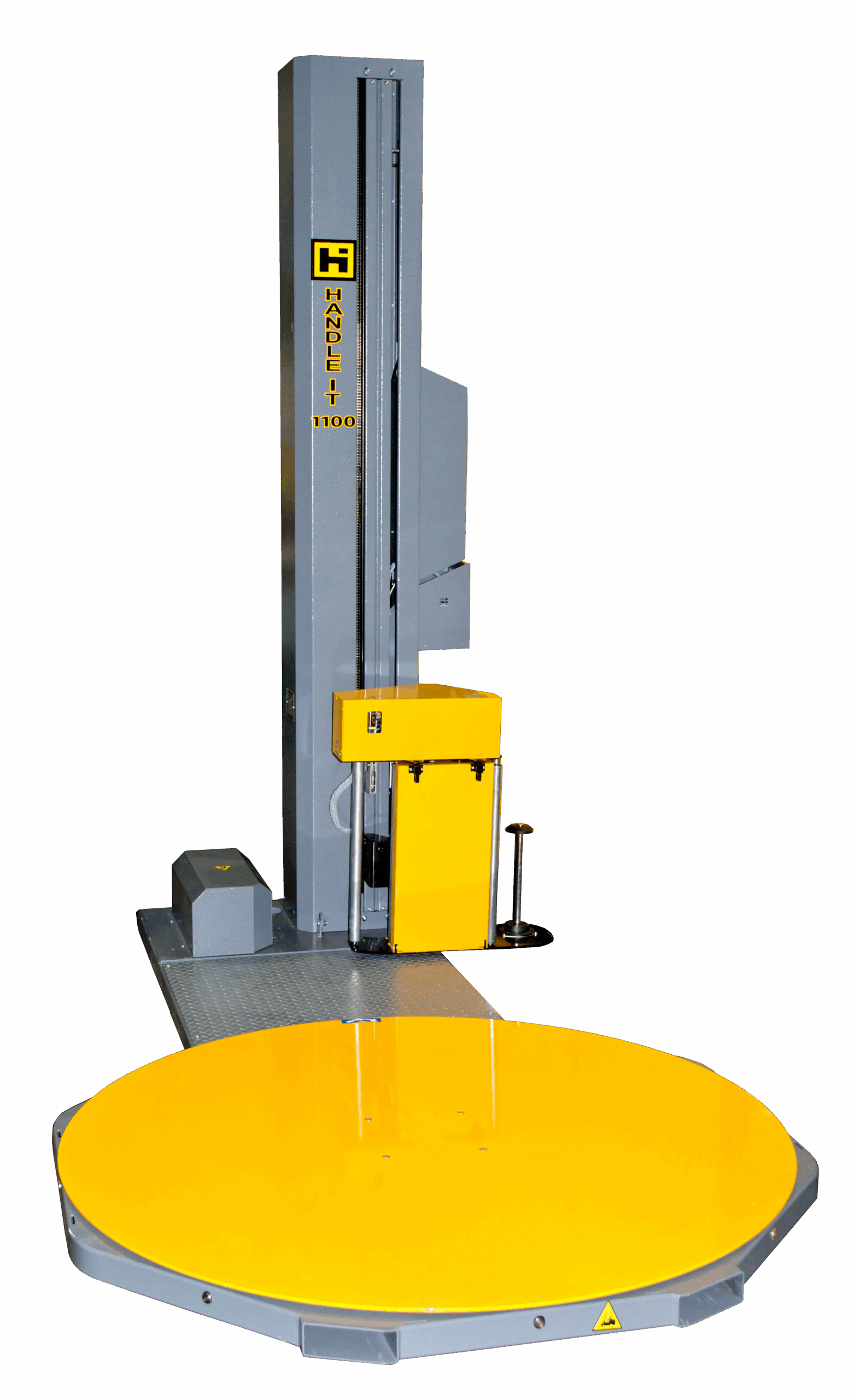

The Duty of Stretch Wrap Machines in Production and Logistics

Stretch Wrap machines play a crucial function in the efficiency of manufacturing and logistics operations. These machines automate the procedure of safeguarding items on pallets, boosting stability throughout transportation and storage space. By firmly covering products in plastic film, stretch Wrap machines reduce the risk of damage brought on by shifting or exterior effects. This not only secures the integrity of the products yet also minimizes waste and the need for additional product packaging materials.In production environments, stretch Wrap equipments add to streamlined process, enabling faster packaging and shipping procedures. They allow companies to manage higher quantities of goods, boosting overall efficiency. In logistics, using stretch Wrap machines ensures that items are effectively secured for transport, reducing the possibility of item loss or damages in transportation. By maximizing load stability, these equipments eventually support cost-efficient procedures, making them indispensable assets in contemporary supply chains.

Typical Indicators of Stretch Wrap Machine Malfunction

When a stretch Wrap Machine starts to breakdown, certain indications can show the need for immediate attention. One usual indication is irregular covering tension, which may result in extremely limited or loosened wraps, compromising product stability. Furthermore, uncommon noises throughout procedure, such as thumping or grinding, can signify mechanical issues that call for evaluation. A reduction in covering speed or failure to complete cycles can also indicate underlying problems, potentially resulting in operational hold-ups. An additional indication is the visibility of movie jams, where the covering product comes to be stuck, interrupting the process. These notifies must not be overlooked if the Machine shows error codes or alerting lights on its control panel. Lastly, visible endure elements, such as rollers or movie dispensers, might suggest that upkeep or fixing is needed to bring back peak capability. Recognizing these indicators early can stop further problems and guarantee effective procedure.

The Impact of Downtime on Operations

Downtime of stretch Wrap makers can significantly impact a company's economic performance, causing considerable monetary losses. In addition, production hold-ups might interrupt supply chains and customer satisfaction, additional aggravating the influence on procedures. Understanding these repercussions is vital for effective Machine repair and maintenance techniques.

Financial Loss Assessment

The influence of equipment failure can significantly disrupt operations, resulting in substantial monetary losses. When a stretch Wrap Machine malfunctions, manufacturing may halt, resulting in discontented customers and unsatisfied orders. This downtime not only affects prompt earnings however can additionally damage long-term service relationships. The costs connected with repair work, combined with lost productivity, can promptly accumulate, straining budget plans. In addition, services may sustain added expenses from overtime salaries for staff who require to compensate for shed time once the Machine is functional again. In an open market, such financial effects can prevent a firm's development and profitability. Expert and timely fixing solutions are essential to minimize downtime and shield economic wellness.

Manufacturing Delays Consequences

Tools failure can cause significant manufacturing delays, impacting various elements of operations. When a stretch Wrap Machine breakdowns, the immediate repercussion is halted product packaging processes, which can create a stockpile in manufacturing routines. This disruption not just influences the flow of items but also pressures labor resources, as staff members may be forced to stand redirect or still efforts to various other jobs. Subsequently, hold-ups can result in unmet shipment deadlines, staining client relationships and potentially leading to shed sales. Additionally, downtime incurs additional expenses associated with fix services and overtime earnings for employees. Eventually, the ripple effect of production delays illustrates the important need for prompt and professional upkeep of stretch Wrap equipment to assure seamless operational continuity.

Benefits of Professional Fixing Solutions

Specialist fixing services for stretch Wrap machines supply a number of key advantages. These services not only enhance equipment durability however additionally contribute to enhanced operational performance and offer cost-efficient maintenance options. By investing in expert repairs, services can guarantee their devices do at peak efficiency gradually.

Improved Devices Durability

Investing in expert repair solutions for stretch Wrap equipments considerably improves their durability. Normal maintenance and timely fixings deal with possible issues prior to they rise, making certain that equipments run at their best. Skilled professionals use specialized expertise and tools to recognize and rectify problems that may not appear to inexperienced operators. This positive method lessens damage, thus expanding the life expectancy of the tools. In addition, the usage of top quality substitute components during fixings additionally contributes to durability. Consequently, business can prevent the costs connected with premature devices failure and replacement. On the whole, professional fixing solutions play a vital function in maintaining the stability and functionality of stretch Wrap machines, inevitably protecting their lasting financial investment.

Raised Functional Efficiency

Maintaining stretch Wrap equipments through professional repair solutions considerably improves functional efficiency. Specialist repair work guarantees that all parts operate at their finest, decreasing the probability of malfunctions that disrupt manufacturing timetables. When equipments are in peak problem, they can operate at their made rate and accuracy, bring about quicker wrapping processes. This performance reduces downtime and permits smoother process, ultimately improving performance. On top of that, properly maintained equipments need less power to operate, adding to improved resource administration. By attending to mechanical problems promptly, professional fixing solutions avoid small troubles from rising into significant failings, guaranteeing that operations run flawlessly. Business can accomplish higher output degrees, fulfill client needs more effectively, and keep an affordable edge in the market.

Cost-Effective Upkeep Solutions

A well-executed repair work solution can greatly lower lasting upkeep prices for stretch Wrap devices. By resolving concerns without delay and effectively, specialist repair work services minimize the threat of considerable damage that can demand pricey replacements. Routine maintenance and prompt fixings assure that equipments run at peak effectiveness, lowering energy usage and product waste. Furthermore, experienced service technicians possess the experience to recognize underlying issues that may not be right away obvious, protecting against future failures. Purchasing professional fixing services additionally extends the life-span of the equipment, offering considerable financial savings with time. Overall, these cost-efficient maintenance remedies not just improve the performance of stretch Wrap devices however additionally contribute to an extra lasting operational my site budget.

Preventative Upkeep for Stretch Wrap Machines

Reliability in stretch Wrap makers depends upon effective preventative maintenance techniques. Routine upkeep is necessary to guarantee peak performance and long life of the equipment. This entails routine assessments, lubrication of relocating components, and timely replacement of worn parts - stretch wrap machine repair near me. By adhering to a structured maintenance routine, drivers can identify possible problems before they escalate right into significant issues, thereby decreasing downtime and pricey repairs.Additionally, cleansing the Machine from particles and deposit is vital, as it can affect performance and rate. Operators needs to additionally keep track of the tension on the wrapping film and adjust settings as needed to protect against film breakage and guarantee protected loads. Training personnel on proper operation and upkeep methods additionally boosts integrity. Eventually, executing a detailed preventative maintenance strategy not just prolongs the life of stretch Wrap devices however likewise contributes to the total effectiveness of packaging operations

Selecting the Right Repair Solution for Your Tools

Frequently Asked Concerns

Just How Commonly Should Stretch Wrap Machines Be Examined for Upkeep?

Stretch Wrap machines must be examined for upkeep a minimum of every 6 months (stretch wrap machine repair near me). Routine assessments assist identify possible issues early, ensuring the makers run efficiently and minimizing the risk of pricey downtime or substantial repairs

Can I Do Fixings on My Stretch Wrap Machine Myself?

While some minor modifications might be feasible, trying extensive fixings on a stretch Wrap Machine can bring about further complications. It is generally a good idea to speak with a professional technician for secure and reliable repair service remedies.

What Is the Average Lifespan of a Stretch Wrap Machine?

The typical life expectancy of a stretch Wrap Machine commonly ranges from 5 to ten years, relying on use strength, upkeep practices, and the top quality of the Machine, affecting its general performance and resilience gradually.

Exist Certain Brand Names Known for Better Resilience in Stretch Wrap Machines?

Certain brands, such as Signode and 3M, are recognized for their sturdiness in stretch Wrap makers. Clients commonly report longer life expectancies and fewer maintenance issues contrasted to various other brand names, making them preferred options in the market.

How Can I Tell if My Machine Requirements an Upgrade As Opposed To Repair Service?

Indicators for upgrading a stretch Wrap Machine consist of constant breakdowns, see this website outdated modern technology, raising operational costs, and inability to fulfill production demands. Assessing performance metrics can assist figure out whether repair work or upgrade is the more sensible alternative - stretch wrap machine repair near me. By securely wrapping products in plastic film, stretch Wrap machines minimize the threat of damage created by moving or exterior influences. Professional fixing services for stretch Wrap equipments use numerous key benefits. Investing in expert repair work solutions for stretch Wrap machines substantially improves their long life. Preserving stretch Wrap equipments through specialist repair solutions significantly improves operational performance. A well-executed repair service can significantly decrease long-lasting upkeep prices for stretch Wrap devices